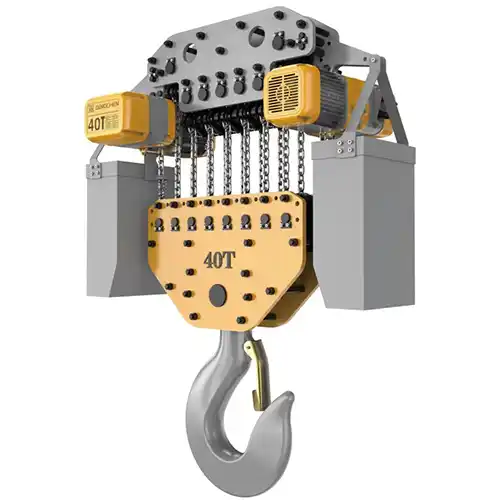

40 Ton + 40 Ton Tandem Hoisting Overhead Travelling Crane System

Advanced electric overhead cranes 40 ton + 40 ton, designed for efficient, synchronized heavy load lifting, optimizing space, precision, safety& cost.

Category: 40 Ton Overhead Crane

Your Trusted 40 Ton Overhead Crane Manufacturer & Supplier

40 Ton + 40 Ton Overhead Cranes for Sale

Advanced Overhead Travelling Cranes for Heavy Load Tandem Operation:

Executive Summary

Purpose of the Case Study

The purpose of this case study is to explore the performance and benefits of using 40 Ton + 40 Ton overhead cranes in heavy load tandem operations. Overhead cranes are essential in various industries, particularly in heavy manufacturing and steel mills. This study focuses on how tandem operations using dual cranes can improve lifting capabilities, operational efficiency, and safety. It also examines the technology behind these cranes, their applications, and the challenges involved in their operation.

Key Findings

- Increased Load Capacity: Tandem operation significantly boosts the lifting capacity. By using two cranes in coordination, loads that are too heavy for a single crane can be safely lifted and transported.

- Improved Precision: Advanced synchronization systems ensure that both cranes move in perfect harmony. This minimizes load swinging and enhances control during operation, making it safer for both workers and equipment.

- Space Optimization: With high-capacity cranes like the 40 Ton + 40 Ton system, operations can be more compact. Businesses can maximize their floor space and achieve higher throughput without the need for larger, more complex setups.

- Efficiency and Cost-Effectiveness: Tandem operation helps reduce operational time and costs. Cranes work faster, minimizing downtime and increasing the overall productivity of the facility. Energy-efficient features also help in lowering operational costs.

- Safety Enhancements: These cranes come with built-in safety systems, such as load balancing and anti-collision features, ensuring that the heavy loads are lifted and moved with minimal risk.

Recommendations

- Adoption for Heavy Industry: Industries dealing with oversized and heavy materials should consider integrating 40 Ton + 40 Ton overhead cranes for their tandem operations. The ability to safely lift larger loads and the improved efficiency are major advantages.

- Regular Maintenance and Monitoring: To keep these cranes running at optimal performance, regular maintenance and monitoring of the synchronization systems are necessary. Preventative care is key to reducing downtime and maintaining safety standards.

- Invest in Operator Training: Proper operator training is essential to fully leverage the advanced capabilities of these cranes. Workers should be skilled in the use of tandem operations, including controlling both cranes simultaneously for maximum safety and efficiency.

- Consider Future Technological Advancements: As technology continues to evolve, it's important to keep an eye on innovations that could further improve crane performance. Upgrading to new systems with better energy efficiency and more advanced safety features can offer long-term benefits.

This case study shows that advanced overhead cranes with tandem operations bring clear benefits in terms of load handling, efficiency, and safety. The findings suggest that these systems are a valuable investment for industries requiring the handling of heavy or oversized loads.

Overview of Heavy Load Tandem Operation

Heavy load tandem operation means using two cranes working together to lift very heavy or large loads that one crane can't handle on its own. The two cranes are synchronized to share the load, making it possible to move materials safely and efficiently.

In industries like steel mills, construction, and manufacturing, these operations are crucial when dealing with oversized equipment or materials. By using two cranes, companies can lift heavier loads with greater stability, reducing the risk of accidents and minimizing damage to both the load and the crane.

Importance of Overhead Cranes in Industrial Applications

The European Style Eletric Hoist Overhead Cranes are vital in many industrial environments because they allow workers to lift and move large and heavy items with ease. These cranes are particularly important in steel mills and manufacturing plants where materials like steel beams, molten metal, and heavy machinery need to be moved regularly.

Some key benefits of overhead cranes include:

- Increased efficiency: They move materials quickly across a facility, saving time compared to manual labor or forklifts.

- Improved safety: Overhead cranes reduce the need for workers to handle heavy loads, lowering the risk of injury.

- Flexibility: Cranes can cover large areas of a plant, lifting materials over obstacles and into different work zones.

In steel mills, for example, overhead cranes are used to handle everything from raw materials to finished products, playing a huge role in the smooth running of operations. They help companies maintain consistent production, optimize floor space, and ensure safety.

Focus of the Case Study

This case study focuses on the use of 40 Ton + 40 Ton overhead cranes in tandem operation. These cranes, when used together, provide the capacity to lift loads that are too heavy for a single crane.

The study will look at how these systems work, the technology that ensures they operate safely and efficiently together, and the specific benefits they offer. We'll also explore the challenges involved, such as the need for proper synchronization, training, and regular maintenance. This case study is focused on industries like steel production, where handling large, heavy loads is a constant need.

Crane Technology and Specifications

Technical Features of 40 Ton + 40 Ton Overhead Cranes

The 40 Ton + 40 Ton overhead crane system is designed to handle heavy lifting operations with precision and safety. Here are some key technical features:

- Load Capacity: Each crane is capable of lifting up to 40 tons, making the tandem system capable of handling loads of up to 80 tons.

- Span: The span, or distance between the crane supports, is designed to cover large areas of a facility, allowing the cranes to move materials across wide spaces without obstruction.

- Lifting Height: These cranes offer adjustable lifting heights, typically ranging from 20 to 30 meters, depending on the needs of the operation. This flexibility is crucial for lifting heavy loads to different heights within the facility.

- Speed: The speed of the cranes is adjustable, allowing operators to control both lifting and traveling speeds to match the load and the task at hand.

- Control Features: The cranes are equipped with advanced control systems, such as radio or pendant controls, to ensure that operators can manage the cranes with precision, even from a distance.

Advanced Technologies

- Synchronization Systems: One of the most important features of the 40 Ton + 40 Ton system is the synchronization technology. This system ensures that both cranes operate in perfect coordination when lifting a load, preventing imbalance or swinging. The cranes work together as a single unit, making the lifting process smoother and safer.

- Load Sensing Technology: Load sensors are integrated into the system to monitor the weight of the load being lifted in real-time. This technology helps prevent overloading, ensuring that the cranes operate within their safe weight limits. It also provides feedback to the operator, helping adjust lifting speeds and strategies for optimal performance.

- Anti-Sway Control: Anti-sway systems are used to reduce the oscillation of the load. This is crucial for safety and precision, especially when lifting large or irregularly shaped materials that can cause the load to swing dangerously.

Design Considerations

Safety Systems:

- Overload Protection: The cranes are equipped with overload protection to prevent them from lifting loads beyond their rated capacity. This is a crucial safety feature that prevents equipment damage and reduces the risk of accidents.

- Emergency Stops: In case of a malfunction or emergency, the cranes are designed with emergency stop systems that immediately halt operations. This feature ensures that the cranes can be stopped quickly if a dangerous situation arises.

Structural Integrity and Materials Used:

- The cranes are built with strong, durable materials to handle the high stresses involved in lifting heavy loads. High-quality steel is used for the structure, ensuring both strength and longevity.

- The design prioritizes rigidity and resilience to withstand the forces generated during lifting and lowering heavy loads. Reinforced components ensure that the crane can operate under high-stress conditions without compromising safety or stability.

Operational Efficiency and Ergonomics:

- The crane system is designed with operator comfort and efficiency in mind. The control cabin or remote control systems are ergonomically designed, allowing operators to control the cranes for long periods without discomfort.

- Ease of Operation: The system's user-friendly interface, combined with automated features like load sensing and synchronization, ensures that operators can handle the cranes with minimal effort while still maintaining high levels of control and precision.

- Maintenance Considerations: Easy access to key components for routine checks and repairs is built into the crane design, which helps reduce downtime and keeps the system running efficiently.

These technical features, safety systems, and design considerations make the 40 Ton + 40 Ton overhead crane system ideal for handling heavy loads in industries like steel manufacturing and large-scale construction, where safety, precision, and efficiency are top priorities.

Benefits of Tandem Operation

Enhanced Load Capacity

Combining two cranes for heavy load lifting significantly enhances the overall lifting capacity. In a tandem operation, two 40 Ton cranes working together can handle up to 80 tons of weight, which would be impossible for a single crane to lift safely. This allows industries to move heavier materials and larger equipment with ease.

- Increased operational efficiency: With two cranes in tandem, operations can be completed faster, as both cranes share the load and work together seamlessly. This reduces the time spent on heavy lifting, resulting in quicker turnaround times for projects.

- Handling oversized loads: Tandem operations are essential when dealing with oversized or irregularly shaped loads, which may be difficult or impossible to manage with a single crane. The additional lifting power helps overcome these challenges.

By combining two cranes, industries can tackle jobs that require extra muscle, all while maintaining high efficiency and safety.

Improved Precision and Safety

One of the key advantages of tandem operation is the ability to maintain precise control over the load, even when lifting extremely heavy weights.

- Synchronized Movement: The advanced control systems in 40 Ton + 40 Ton cranes ensure that both cranes operate in perfect harmony. This synchronization minimizes the risk of imbalance or swinging, which could damage the load or cause accidents.

- Load Stability: These systems work together to keep the load stable, even as it moves across the facility. Operators can adjust the movement of the cranes to handle delicate or irregularly shaped items without risking safety.

- Minimization of Load Swinging: Heavy loads can often swing as they are lifted, posing a risk to workers and equipment. Tandem operations, with their synchronized movement, reduce load swinging significantly, allowing for smoother and safer transport.

- Maximized Precision: The precision of tandem operation ensures that loads are placed accurately where needed, which is crucial in tight spaces or when dealing with large machinery that requires exact positioning.

These advanced safety and control features not only improve the efficiency of operations but also make them safer for workers and equipment.

Space Optimization

In industrial settings, space is often limited, and maximizing the available area is critical for improving operational flow and efficiency. Tandem operations with high-capacity cranes help achieve this by utilizing floor space more effectively.

- Efficient Use of Space: With two cranes working together, industries can move large, heavy loads across greater distances without needing to use more floor space or additional equipment. The high lifting capacity means that large items can be moved more efficiently, without needing more cranes or equipment.

- Maximized Floor Efficiency: High-capacity cranes allow for a denser arrangement of materials and equipment on the factory floor. This minimizes the space needed for lifting and moving heavy loads, freeing up valuable room for other activities or equipment.

By optimizing the available space, tandem operations help industries boost productivity while reducing the need for expensive facility expansions.

Applications and Industry Use Cases

Steel Mills and Heavy Manufacturing

In industries like steel production and heavy manufacturing, the need for lifting and transporting large, heavy materials is constant. Here's how 40 Ton + 40 Ton overhead cranes in tandem operation are used:

Steel Mills: These cranes are often used to lift and move steel beams, large coils of steel, and molten metal. Steel mills require reliable, high-capacity cranes to handle materials that are both heavy and hot, making precision and safety crucial. Tandem operation ensures that these massive loads are lifted evenly, preventing swings that could cause accidents or damage. In a steel mill, a tandem crane system may be used to move hot steel slabs from one part of the facility to another. Since these slabs can weigh over 60 tons, a single crane would struggle to handle them safely, so two cranes work together to move the load quickly and safely.

Heavy Manufacturing: Large manufacturing plants often deal with heavy machinery, oversized parts, or bulky components that need to be moved between different stages of production. Tandem cranes allow for precise positioning of these parts, minimizing delays in the manufacturing process.A manufacturing plant producing large equipment might use tandem cranes to move machine components from the assembly line to the storage area. The cranes work together to lift and position these heavy parts without taking up extra floor space or requiring additional personnel.

Other Industries

While steel mills and manufacturing plants are the primary users of heavy load tandem cranes, other industries also benefit from their capabilities:

- Construction: In construction, tandem cranes are often used to lift large concrete beams, steel structures, or pre-fabricated parts that are too heavy or bulky for a single crane. The ability to coordinate two cranes for lifting provides greater flexibility and efficiency on large construction sites. In the construction of tall buildings or bridges, two cranes working together can lift and position large steel beams or concrete panels quickly and safely.

- Shipyards: Shipyards use overhead cranes to handle large ship components, such as hull sections, engines, or massive machinery. Tandem cranes are particularly useful when building or repairing large vessels, where weight distribution and precise positioning are critical. When assembling large ships, tandem cranes may lift and position parts of the hull, ensuring that massive sections are safely moved without risk of tilting or damage.

- Large-Scale Logistics: In warehouses or ports, tandem cranes can be used to load and unload heavy cargo containers. By using two cranes together, these operations become more efficient and can handle larger, heavier items than would be possible with a single crane.In a port, tandem cranes can lift and move shipping containers from a dock to a truck or storage area, significantly speeding up unloading times and improving cargo management.

Challenges in Heavy Load Handling

While tandem operations provide significant benefits, they also come with unique challenges that industries must address:

- Synchronization and Coordination: Ensuring that both cranes work in perfect harmony is critical. Any failure to synchronize the cranes can lead to imbalance or damage to the load. Operators must be trained to control both cranes simultaneously, and systems must be in place to ensure smooth communication between the two cranes.

- Operator Expertise: The complexity of tandem operations requires highly skilled operators. It's not just about moving the cranes in sync – operators must be able to anticipate load shifts, adjust for uneven lifting, and respond to changing conditions on the ground. Adequate training and experience are necessary to handle these challenges safely.

- Maintenance and Downtime: The added complexity of operating two cranes together means that maintenance is more involved. Any failure in one crane could disrupt the entire lifting operation, leading to costly downtime. Regular inspections, load sensors, and preventive maintenance are crucial for keeping these systems running smoothly.

- Environmental Conditions: External factors, such as wind, weather, or uneven ground, can impact the stability and safety of tandem operations. These challenges must be considered when planning and executing lifts, especially in industries like construction and shipbuilding where outdoor operations are common.

By addressing these challenges, industries can take full advantage of the benefits of tandem crane operations, ensuring safe, efficient, and reliable heavy load handling.

Operational Efficiency and Cost-Effectiveness

Reduction in Operational Time

Tandem operations significantly improve throughput by allowing heavy loads to be moved quickly and efficiently. With two cranes working together, lifting and moving large, heavy materials becomes faster than if only one crane was used. This directly impacts the overall production speed and reduces delays in operations.

- Faster Load Movement: Two cranes can share the workload, reducing the time it takes to move heavy loads across the facility. This speeds up tasks such as loading, unloading, and transporting materials, improving overall plant or warehouse efficiency.

- Reduced Downtime: Because tandem cranes allow for more efficient handling of heavy loads, there's less need to stop and start operations for adjustments. This minimizes downtime, ensuring that more time is spent on productive tasks rather than waiting for equipment to be repositioned or realigned.

This increase in operational speed boosts throughput, meaning that more tasks are completed in a shorter period, leading to higher overall productivity.

Cost Savings

The use of tandem crane systems can lead to significant cost savings over time. Several factors contribute to the long-term return on investment (ROI) and reduced operational expenses:

- Long-Term ROI: While the initial investment in high-capacity cranes might be substantial, the increased efficiency and reduction in downtime provide a strong return on investment over time. The ability to handle larger loads without the need for additional equipment or workforce means that the cranes pay for themselves relatively quickly.

- Maintenance Costs: Tandem crane systems are designed with durability in mind, which means fewer repairs and lower long-term maintenance costs. With proper maintenance schedules, the systems can run smoothly for years, minimizing unexpected repair costs and extending the lifespan of the equipment.

- Reduced Labor Requirements: Since tandem cranes can lift and move heavier loads with fewer workers, companies can reduce the number of personnel needed for certain tasks. This leads to savings on labor costs, as fewer workers are required to operate the cranes and move materials. Furthermore, with more advanced automated features, the need for manual handling is reduced, cutting labor expenses even further.

By optimizing the efficiency of operations and reducing the need for extensive labor, tandem cranes help companies lower their overall operating costs.

Energy Efficiency

Energy usage is a key factor when evaluating the cost-effectiveness of any heavy equipment, and tandem cranes are designed with energy efficiency in mind:

- Power Usage: Tandem cranes are engineered to be power-efficient, utilizing advanced motors and control systems that optimize energy consumption. This helps reduce overall energy costs, particularly in large-scale operations where crane systems are used frequently throughout the day.

- Energy-Saving Technologies: Many modern crane systems incorporate energy-saving features, such as regenerative braking. This technology captures energy that would otherwise be lost during the crane's braking process and returns it to the system, reducing power consumption and lowering costs.

- Impact on Operational Costs: By reducing energy consumption, tandem crane systems help keep operational costs lower over time. This is especially beneficial in large operations, where the cumulative energy savings can make a significant impact on the bottom line.

In the long run, the energy efficiency of these systems helps companies save money on electricity, contributing to a more sustainable and cost-effective operation.

Overall, tandem operations offer substantial benefits in terms of reducing operational time, lowering maintenance and labor costs, and improving energy efficiency. These factors combine to make tandem crane systems a smart investment for companies seeking to optimize their heavy load handling while maintaining a focus on cost-effectiveness.

Safety and Compliance

Safety Features in 40 Ton + 40 Ton Cranes

Safety is paramount when using heavy load tandem cranes, and the 40 Ton + 40 Ton crane system comes equipped with several advanced safety features to ensure smooth and secure operations:

- Load Balancing: Tandem cranes are designed to balance heavy loads evenly between the two cranes. This prevents the load from tipping or swinging dangerously, reducing the risk of accidents and damage to both the load and surrounding equipment.

- Anti-Collision Systems: These cranes are equipped with anti-collision technology that prevents them from coming into contact with each other or with other obstacles in the operational area. This is particularly important when two cranes are operating in close proximity, ensuring that they do not collide while lifting or moving heavy loads.

- Safety Monitoring: Advanced safety monitoring systems are integrated into the cranes to continuously track the condition of the load, the crane's mechanical status, and any potential safety hazards. These systems provide real-time feedback to operators, helping them make adjustments as needed and ensuring that operations stay within safe parameters.

By incorporating these safety features, the cranes provide enhanced protection for both the operators and the materials being lifted, helping to prevent accidents and maintain smooth, secure operations.

Compliance with Industry Standards

Safety and compliance with industry standards are critical when operating heavy lifting equipment. The 40 Ton + 40 Ton crane system is designed to meet both international and local safety regulations:

- International Standards: The crane system is designed to comply with widely recognized international safety standards, such as ISO 9001 for quality management and ISO 13849 for safety-related control systems. These standards ensure that the cranes meet high levels of safety and reliability, offering peace of mind to operators and facility managers.

- Local Standards: In addition to international standards, the cranes must adhere to local regulations like those set by OSHA (Occupational Safety and Health Administration) in the United States or equivalent bodies in other countries. These regulations cover aspects such as load capacity, structural integrity, and operator safety. Ensuring compliance with these standards reduces the risk of fines, accidents, and other legal issues, while maintaining a high standard of operational safety.

Meeting these standards helps ensure that the cranes are safe to operate and that the facility adheres to necessary regulatory requirements, protecting both the workforce and the company.

Operator Training and Certification

For safe and efficient operation of tandem cranes, it is crucial that operators are highly skilled and well-trained. Proper training ensures that the cranes are used to their full potential while maintaining the safety of all involved.

- Skilled Operators: Operating a tandem crane system requires more than just basic crane knowledge. Operators must be trained to understand the complexities of synchronizing two cranes, adjusting to changes in load weight, and responding to potential hazards. Proper training allows operators to anticipate challenges and make quick decisions to keep operations safe and smooth.

- Certification: Many regions require crane operators to be certified before operating high-capacity equipment. Certifications typically involve both classroom instruction and hands-on training, followed by testing to ensure that the operator understands safety protocols and operational procedures. Certifications may be issued by recognized bodies such as the National Commission for the Certification of Crane Operators (NCCCO) in the U.S. or other relevant organizations worldwide.

- Ongoing Training: Even after certification, it's essential for crane operators to undergo periodic refresher courses and safety drills. This ensures that they stay updated on any new safety protocols, technologies, or regulatory changes that may affect crane operations.

By investing in proper operator training and certification, companies can ensure that their cranes are operated safely, reducing the risk of accidents and improving overall operational efficiency.

In summary, the 40 Ton + 40 Ton overhead crane system is built with a strong focus on safety, from load balancing to anti-collision systems. Adherence to both international and local safety standards ensures compliance with the necessary regulations. Proper operator training and certification are also essential for safe and effective operation, helping to maintain high safety standards while maximizing operational efficiency.

Challenges and Considerations

Integration with Existing Systems

When implementing a 40 Ton + 40 Ton tandem crane system, one of the key considerations is how well the new equipment integrates with existing systems and infrastructure:

- Compatibility with Existing Equipment: In many industrial settings, cranes are often part of a larger material handling system. Integrating tandem cranes into this system requires careful planning to ensure that they can work seamlessly with other machinery, such as conveyors, lifts, or automated systems. Any incompatibility could lead to inefficiencies or even operational delays.

- Infrastructure Modifications: Existing facilities may need structural adjustments to accommodate the new cranes. This could involve reinforcing building supports, adjusting power systems, or ensuring that the crane's control systems integrate with the facility's central monitoring system. The cost and time required for these modifications need to be carefully considered.

Proper planning and coordination during the installation phase are critical to avoid disruptions and to ensure smooth integration with other operational systems.

Maintenance and Downtime

Like any heavy-duty machinery, the 40 Ton + 40 Ton cranes require regular maintenance to ensure that they continue to operate efficiently and safely:

- Regular Maintenance Schedules: To minimize unexpected breakdowns, it's essential to have a well-planned maintenance schedule. Regular inspections, lubrications, and mechanical checks help prevent wear and tear from affecting the crane's performance. Proactive maintenance also extends the lifespan of the equipment and ensures it runs smoothly without interruptions.

- Downtime Management: Any downtime in heavy lifting operations can result in significant productivity losses. Scheduling maintenance during off-peak hours or during planned production breaks helps minimize the impact on daily operations. Additionally, it's important to have backup equipment or contingency plans in place in case a crane needs repairs during critical periods.

- Troubleshooting: When a mechanical issue arises, quick troubleshooting is crucial to identify the root cause and resolve it before it leads to more serious damage. Having a skilled maintenance team and access to replacement parts reduces downtime and helps keep operations on track.

Efficient maintenance and well-planned downtime management are vital to keeping the crane system in top working condition, ensuring that the operation remains productive and cost-effective.

Operational Challenges

Handling large, heavy, and irregularly shaped loads comes with unique challenges that must be addressed to maintain smooth operations:

- Large and Irregularly Shaped Loads: Many industries, such as steel mills and construction, deal with loads that are not uniform in shape or size. Tandem cranes are designed to handle such loads, but the operator must take extra care to ensure proper load distribution. Irregularly shaped loads can cause the cranes to become unbalanced if not properly secured, potentially leading to tipping or swinging.

- Precision Handling: Precision is key when moving large or fragile loads. Tandem cranes must work in perfect synchronization to ensure that the load is lifted and moved accurately to its designated location. A lack of precision can lead to costly errors, such as damaging the load or other equipment, or causing delays in the operation.

- Coordination Between Operators: In tandem operations, both crane operators must be in constant communication to ensure that both cranes are working in sync. This requires a high level of coordination and attention to detail. Any breakdown in communication or coordination can result in dangerous situations, including the load shifting or swinging unexpectedly.

Addressing these operational challenges requires well-trained operators, precise load planning, and advanced control systems to ensure the cranes are used effectively and safely.

In conclusion, integrating tandem cranes with existing systems, managing maintenance, and handling operational challenges are all important factors that must be carefully considered. With proper planning, training, and maintenance, these challenges can be overcome, ensuring that the 40 Ton + 40 Ton cranes deliver optimal performance and efficiency.

Conclusion

Summary of Key Findings

The use of 40 Ton + 40 Ton overhead cranes in tandem operation offers a range of benefits for industries that handle heavy loads, including:

- Enhanced Load Capacity: Tandem operations significantly increase lifting capabilities, allowing industries to handle loads of up to 80 tons efficiently and safely.

- Improved Precision and Safety: Advanced control systems ensure synchronized movement between cranes, reducing load swinging and increasing operational safety and accuracy.

- Space Optimization: High-capacity tandem cranes allow industries to optimize their available space by lifting heavy loads more efficiently, freeing up valuable floor area for other operations.

- Cost-Effectiveness: The combination of increased efficiency, reduced downtime, lower labor costs, and energy-saving technologies leads to substantial long-term cost savings.

- Safety and Compliance: Tandem cranes come equipped with state-of-the-art safety features and comply with international and local safety standards, ensuring both operator and equipment safety.

Final Recommendations for Industry Adoption

For industries considering the adoption of 40 Ton + 40 Ton tandem cranes, the following recommendations can help ensure successful integration:

- Invest in Operator Training: Given the complexity of tandem operations, companies should prioritize comprehensive operator training and certification to ensure safe and efficient use of the cranes.

- Plan for Integration with Existing Systems: Before adopting tandem cranes, businesses should evaluate their existing infrastructure and plan for potential modifications to accommodate the new equipment. Compatibility with existing systems will help prevent operational disruptions.

- Develop Regular Maintenance Schedules: To reduce downtime and avoid unexpected repairs, companies should implement proactive maintenance schedules and ensure timely inspections and troubleshooting.

- Focus on Safety: It is essential to regularly review safety protocols and ensure that all operators and maintenance teams are fully aware of the risks involved in tandem operations. Enhanced safety systems and regular safety drills should be standard practice.

By following these recommendations, industries can maximize the benefits of tandem cranes while minimizing potential challenges.

In conclusion, adopting 40 Ton + 40 Ton tandem cranes provides numerous operational benefits, from increased lifting capacity and improved safety to cost savings and optimized space utilization. As crane technology continues to advance, the potential for even greater efficiencies and innovations will further enhance the value of these systems in heavy load operations.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch